Paper Size |

Artwork Size(With Bleed Area) |

Finished Size(After Trimming) |

|---|---|---|

| Business Cards | 91mm x 61mm | 85mm x 55mm |

| Compliment Slips / DL | 216mm x 105mm | 210mm x 99mm |

| A7 | 80mm x 111mm | 74mm x 55mm |

| A6 | 111mm x 154.5mm | 105mm x 148mm |

| A5 | 154.5mm x 216mm | 148.5mm x 210mm |

| A4 | 216mm x 303mm | 210mm x 297mm |

| A3 | 303mm x 426mm | 297mm x 420mm |

| A2 | 426mm x 600mm | 420mm x 594mm |

| A1 | 600mm x 847mm | 594mm x 841mm |

| A0 | 847mm x 1195mm | 841mm x 1189mm |

Artwork & Production Guide

Supplying Artwork

PDF Format

Artwork should preferably be supplied as press ready PDFs with 3mm bleed and with simple trim marks. These marks need to be outset by 6 point so they do not touch the cut size of the document (in other words away from the page edge by 3mm). When you create your PDF files you must manually select print and choose the 'press quality' setting, they should be print optimized, images at 300dpi (as a lesser resolution they may appear blurry or pixelated), with all fonts embedded. This is especially important when converting Microsoft Word, Publisher, Excel and PowerPoint documents to PDF to ensure no graphics are missing or reflow of text occurs. Do not use layers; please reduce everything to the background layer/flatten the image before sending.

Fonts

Ideally all fonts need to be embedded within the PDF file to make sure that the fonts used in the creation of the artwork are replicated when printed. If not they may be substituted and not match those used in the artwork.

Images/imported graphics

Images or graphics should be supplied as CMYK and at a resolution of 300dpi (when placed at actual size).

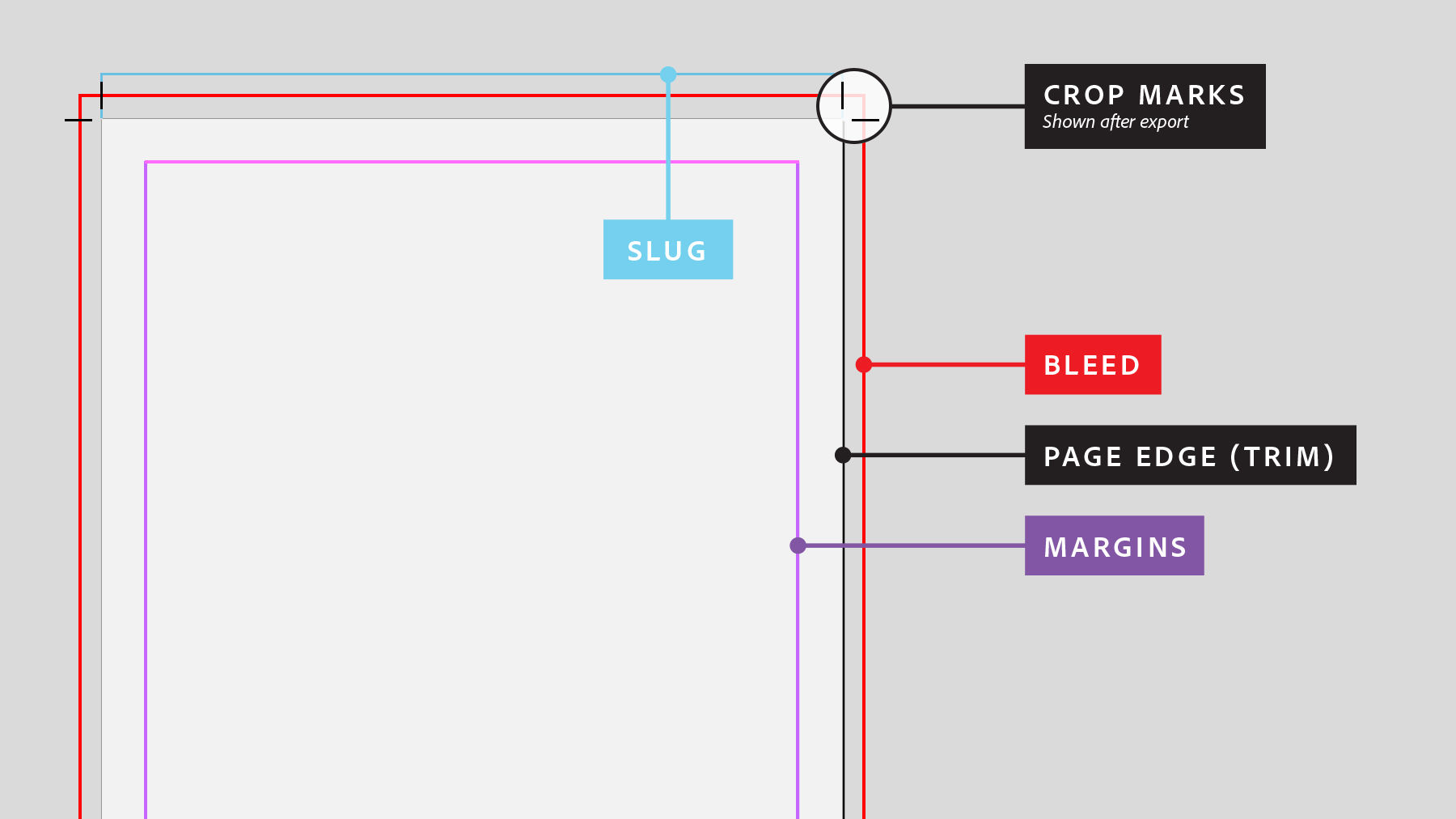

Bleed

All artwork must have 3mm bleed if the image is required to extend right to the edge of the paper. We also recommend that any text is kept inside a margin at least 10mm away from the edge of the page and - as explained above - the crop marks are outset by 6 point so they do not touch the cut size of the document.

Do I need bleed?

Bleed is the term for "overlapping the edge" and is required when pictures, lines or backgrounds are printed right to the edge of the paper. For example, if you want your business cards entirely covered by a picture, the size of the picture box would need to bleed past the trimmed edge of the paper in all directions. Failing to bleed the background may result in white lines or gaps showing around the edge when it is cut down to size on the press, guillotine or bookletmaker.

Sizes

Ensure your file is at the correct file dimensions as you require to be printed, sizes are listed below:

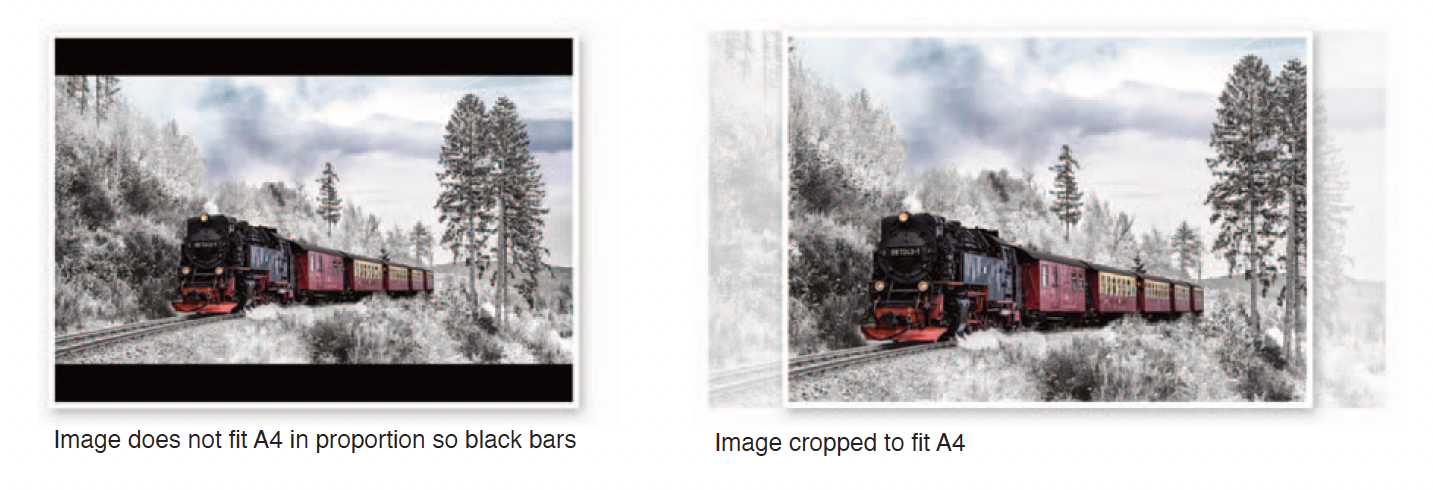

Proportion (often said as “in pro”)

This is the relationship of the width and height of an image or the ratio between the dimensions. It’s important to understand what this means because it can affect the final product when you print. If the file supplied does not re-scale in proportion to the size ordered, then to avoid enlarging the image one way resulting in a non-equal stretching of the image, then cropping of the image will be necessary where some part of the image is outside of the print area will not be printed.

How many pages?

The “Rule of 4” in printing is the requirement that the page count of a standard book or booklet needs to be a multiple of four. If you’re preparing a book, catalogue, magazine, or any style of printed booklet that requires stitch or staple binding, it’s important to remember one rule: books have pages in multiples of 4. When you’re planning your content, keep in mind that you will be adding pages in multiples of 4 to avoid having unnecessary blank pages. Why does this happen? It’s due to the production process of these booklets. Imagine a normal sheet of paper in landscape orientation, fold that piece of paper in half - one sheet turns into 4 pages.

Lamination vS Encapsulation

Encapsulation

A thick layer of plastic is applied to both sides of a document, with the plastic extending beyond the edges to create a watertight seal. This process is more suitable for documents that need robust protection, such as outdoor posters or materials that are handled frequently. Encapsulation is irreversible and is often used for one-off or low quantity printing.

Lamination

A thin layer of plastic is applied to both sides of a document but there is no lip around the edges. This process is less protective than encapsulation and is not watertight because moisture can get in through the unsealed edges. Lamination is a conventional method that is often used to enhance the durability and appearance of documents.

If you have any queries or need an explanation please don’t hesitate to get in touch.